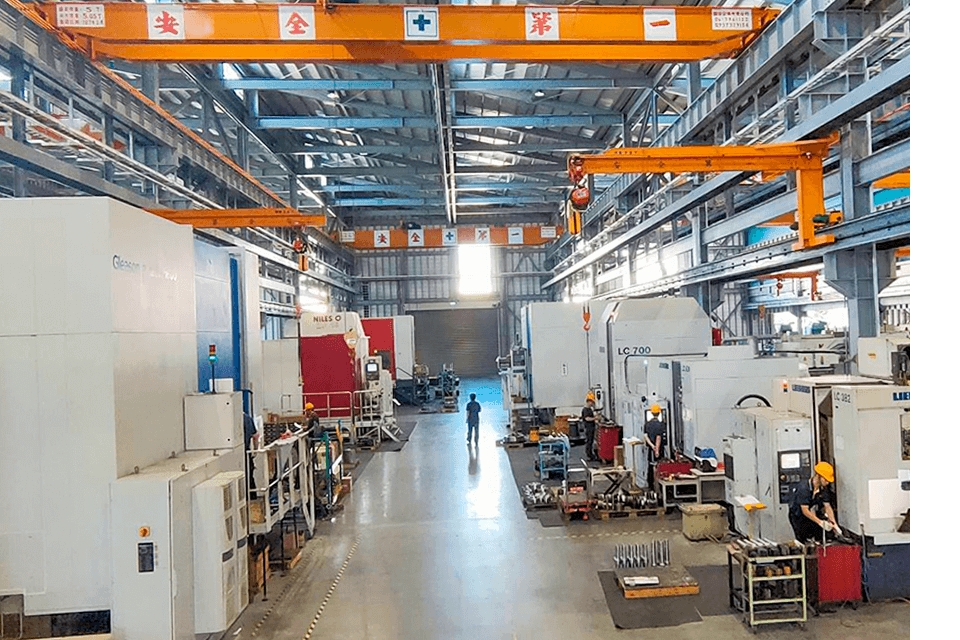

HOFLER - GER

NILES ZX 1000 - GER

NILES KX 500 - GER

NILES ZE 800 - GER

NILES ZE 400 - GER

Equipments

| Gear Grinding | |

|---|---|

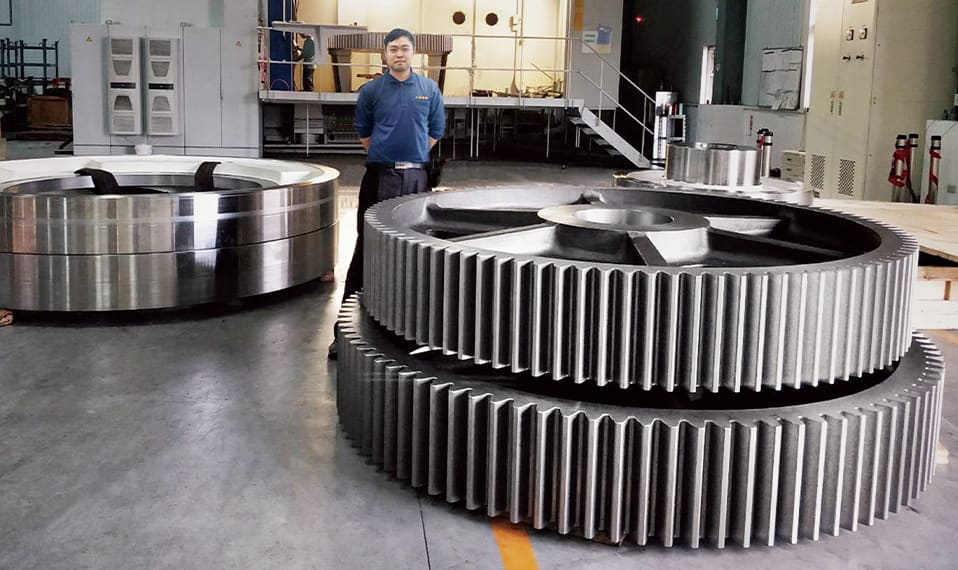

| Max Module | M30 |

| Max Gear Diameter | Ф2,000mm |

| Gear Hobbing | |

|---|---|

| Max Module | M30 |

| Max Gear Diameter | Ф3,300mm |

State-of-the-Art Manufacturing Equipment for Precision Gear Production

German NILES & HOFLER Gear Grinder

Gears Facilities Features

- High-Precision Structure: The latest mineral cast structure ensures non-deformation and maximum precision for equipment and gear parts.

- Wear-Free Rotary Table: Hydrostatic rotary table ensures long-term accuracy and durability.

- Advanced CNC Technology: Close-looped CNC direct-drive system with in-form grinding technology enables gear grinding up to DIN 1 "3 grade.

- Integrated Cutting & Inspection: Combines cutting, grinding, and on-board CNC auto gear-profile inspection for efficiency.

- High-Speed Machining: CNC multi-axis system powered by Siemens Super 8400 program for optimal performance.

MACHINING EQUIPMENTS

-

Gear Grinders

-

Gear Hobbing Machines

LIEBHERR - GER

PFAUTER - GER

LORENZ - GER

NIHON KIKAI - JAP

NACHI - JAP

SEIWA - JAP -

Surface Grinders

OKAMOTO - JAP

PROTH - TW -

CNC Lathes & Machining Centers

YOU JI - TW

HITACHI - JAP

HONOR SEIKI - TW -

Internal Cylindical Grinders

SIELEMANN - GER

TAISEI - JAP

PALMARY- TW -

Gear Chamfering

CROSS - USA -

Key Seaters

MURATA - JAP

FROMAG - GER -

Slotting Machines

YAMAGE - JAP

EASTAR - TW -

Gear Testers

OSAKA SEMITSU - JAP

KLINGELNBERG - GER -

3D Measurung Machine

MITUTOYO - JAP

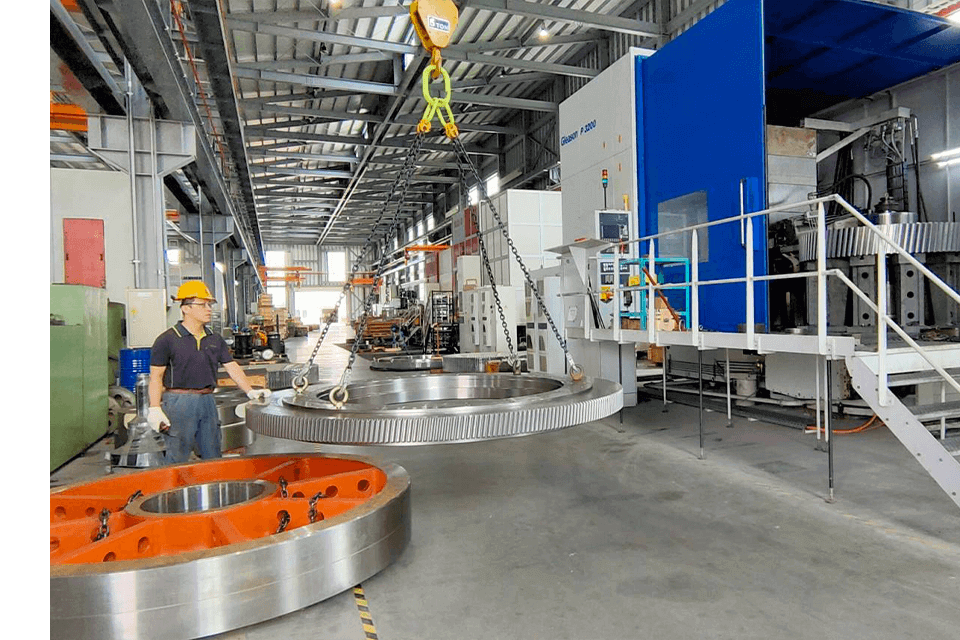

MANUFACTURING PROCESSES

-

Lathes

-

Slotting

-

Hobbing

-

Heat Treating

-

Surface Grinding

-

Internal Cylindrical Grinding

-

Teeth Grinding

GEARBOXES ASSEMBLY CAPABILITY

-

Huge warehouse, all different gearboxes models parts and components.

-

Gears cleaning.

-

SKF bearings induction heaters allow a smooth assembly of bearings rollers with the gears and gears.

-

Gears and gears shafts inspection following by gearbox full assembly.

-

Pipes, breathers, oil filter, plate heat exchanger, oil pump installation.

-

Gearbox dynamic inspection.

-

Gearbox static inspection.