Co-rotating Parallel Twin Screw Extruders

Co-rotating Parallel Twin Screw Extruders: Advanced Solutions for High-Performance Compounding

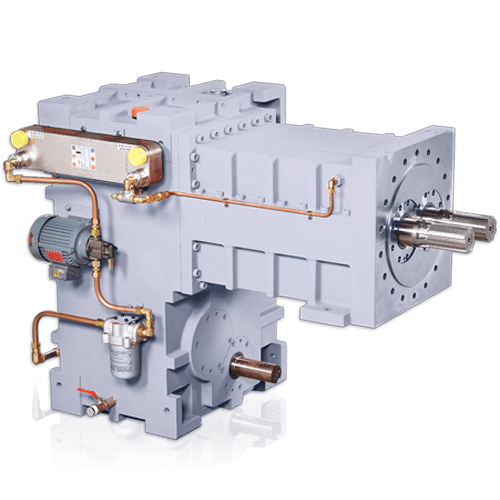

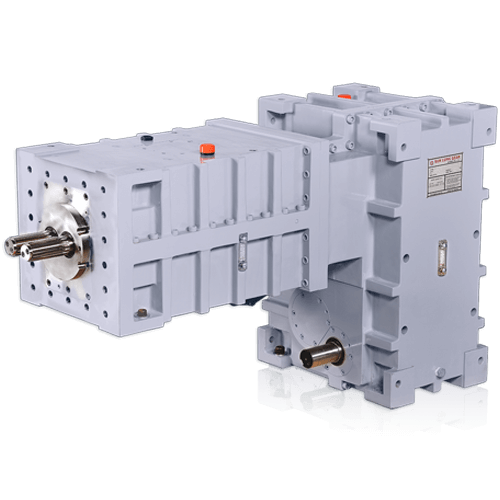

Co-rotating Parallel Twin Screw Extruders are essential in the plastic manufacturing industry for applications requiring high output, superior compounding, and consistent production of masterbatch granules. These extruders excel in blending polymers, fillers, and additives, ensuring uniform material quality. A reliable and precisely engineered twin screw gearbox is the cornerstone of achieving these results.

At SUN LUNG, we specialize in designing high-quality twin screw extruder gearboxes, providing manufacturers with robust solutions tailored to meet demanding production environments.

Applications of Co-rotating Parallel Twin Screw Extruder Gearbox

- High Concentration Masterbatch Production – For producing color masterbatches and functional additives, the gearbox for twin screw extruder enables consistent mixing and precise torque transmission, ensuring top-notch output quality. Our innovative designs cater to high-capacity production needs, helping manufacturers meet market demands efficiently.

- Polymer Compounding – When blending polymers with reinforcements, fillers, or additives, the performance of the twin screw extruder gearbox directly impacts product quality. SUN LUNG’s advanced gearboxes ensure uniform dispersion and seamless operation, supporting industries such as engineering plastics, automotive, aerospace, and electronics.

- Recycling and Reprocessing – In the era of sustainability, custom gearbox solutions are critical for recycling post-consumer and industrial plastics. Our gearboxes are built to handle high-torque operations and recycled materials, ensuring durability and continuous output in demanding environments.

- Specialty Plastics Production – For high-precision applications like medical or electronics-grade plastics, SUN LUNG offers twin screw extruder gearbox expertise to deliver tailored solutions, meeting the specific requirements of specialty production lines.

Why Choose SUN LUNG for Co-rotating Parallel Twin Screw Extruder Gearboxes?

- Customization for Unique Applications – SUN LUNG provides custom gearbox solutions designed to address specific production challenges. Our gearboxes integrate seamlessly with various extruder configurations, ensuring optimized performance.

- High-Precision Engineering – Our twin screw gearbox designs are crafted with high-strength metal materials, durable gear data design, strict production processes, and high-precision gear processing equipment, ensuring tight tolerance control and stable operation, even under high-load conditions.

- Long-Term Durability – We use premium components like SKF bearings and NOK oil seals, along with advanced lubrication and cooling systems, to guarantee long-lasting reliability and efficiency for our twin screw extruder gearboxes.

Our gearboxes for co-rotating twin screw extruders deliver stable torque and long-term reliability for demanding compounding lines.

Contact us today