Counter-rotating Parallel Twin Screw Extruders

Counter-rotating Parallel Twin Screw Extruders: Precision Gearbox Solutions for PVC Applications

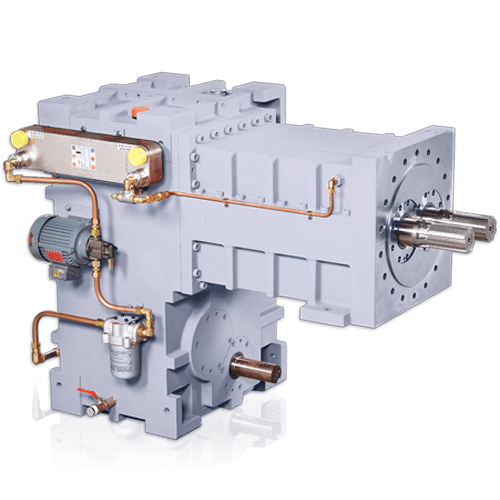

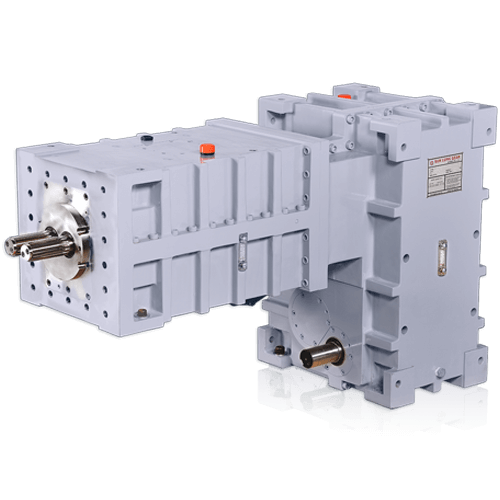

The gearbox for Counter-rotating Parallel Twin Screw Extruders is specifically designed for PVC pipe, sheet, and profile production, where precision, durability, and performance are essential. With an emphasis on low-speed operation and extremely high torque, this solution is ideal for processing thermal-sensitive PVC materials, ensuring consistent and reliable results in low-temperature production processes.

At SUN LUNG, we provide innovative twin screw extruder gearbox design that optimizes gear and shaft arrangements, delivering superior torque and stable output capacity. Our gearboxes are built with a solid structure to meet the rigorous demands of industrial PVC production.

Applications of Counter-rotating Parallel Twin Screw Extruders

- PVC Pipe Production – The twin screw gearbox is critical for manufacturing PVC pipes used in construction, plumbing, and infrastructure. It ensures consistent torque and smooth operations, supporting high-volume production with exceptional output stability.

- PVC Sheet Extrusion – For producing durable and precise PVC sheets, SUN LUNG’s twin screw extruder gearbox offers high performance and reliability, maintaining dimensional accuracy and quality of output product under continuous operations.

- PVC Profile Manufacturing – In applications like window frames, door profiles, and decorative trims, the gearbox for twin screw extruder is optimized for stable performance and precise torque delivery, enabling the production of complex profiles with high surface quality.

Why Choose SUN LUNG for Counter-rotating Parallel Twin Screw Extruder Gearboxes?

- Advanced Twin Screw Extruder Gearbox Design – Our gearboxes are engineered to handle high torque production and various low-speed operating requirements, making them ideal for thermal-sensitive PVC applications. The optimized gear data, high-precision gear production, and high-torque gear configuration ensure smooth and efficient performance.

- High-Quality Components for Longevity – SUN LUNG utilizes premium SKF and INA bearings, combined with an effective cooling and forced lubrication system, ensuring long-term reliability and operational efficiency for all custom-made gearbox solutions.

- Tailored Solutions for Industrial Applications – As leading twin screw extruder gearbox manufacturers, we offer custom-made gearbox designs to meet specific production requirements, ensuring seamless integration with your extruder systems.

- Energy Efficiency and Operational Stability – Our innovative designs focus on reducing energy consumption while maintaining consistent torque and output capacity, providing manufacturers with eco-friendly and cost-effective solutions.

From pipes to profiles, our twin screw gearboxes ensure consistent output and reliable performance.

Contact us today