Metalworking Machine

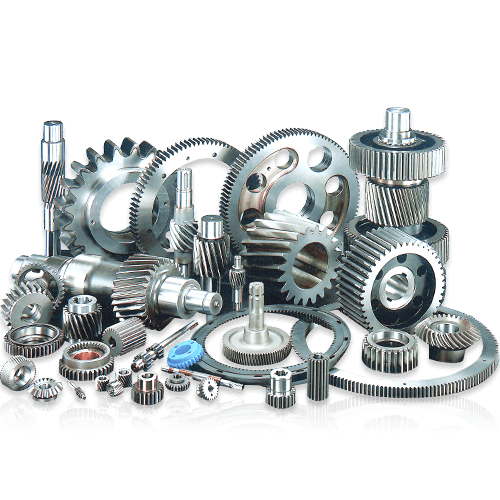

Precision Gears for Large-Scale Metal Processing Machines

In the world of metal processing machines, precision and reliability are key to achieving exceptional results. Sun Lung Gear is proud to be a trusted partner for manufacturers of large-scale equipment, particularly large vertical CNC turning and milling composite machines, which are essential for heavy-duty machining operations. At the core of these machines are precision gears, which play a critical role in enabling the smooth rotation and stability of their massive gear turntables during high-precision tasks.

Why Precision Gears Matter in Metal Processing Machines

Precision gears are essential for optimizing the performance of large metal processing machines in the following ways:

- Ensuring Smooth Rotation and Stability: In large CNC machines, the worktable's rotation must be stable and vibration-free to ensure accuracy in cutting and machining processes. Precision gears ensure seamless power transmission, maintaining the exact rotational speed and torque required for consistent performance.

- Handling Heavy-Duty Loads: Metal processing machines often handle extremely heavy components, requiring gears that can endure significant loads without compromising performance. Sun Lung Gear's precision gears are engineered with high-strength materials and advanced manufacturing techniques to withstand these demanding conditions.

- Enhancing Machining Accuracy: The precision of the gear turntable directly affects the quality of the machined parts. Sun Lung Gear's expertise in gears applications ensures that every gear is crafted with meticulous attention to detail, reducing mechanical errors and ensuring exceptional machining accuracy.

Sun Lung Gear: A Leader in Precision Gear Manufacturing

Sun Lung Gear is a recognized leader among Precision Gear Manufacturers, offering solutions tailored to the unique needs of metal processing machines. Our capabilities include:

- Large Gear Processing Capacity: With the ability to process gears up to 3.2 meters in diameter, we meet the requirements of even the largest CNC machines, ensuring reliable operation for large-scale projects.

- Exceptional Processing Precision: Our advanced manufacturing processes guarantee the high accuracy necessary for critical machining applications, minimizing downtime and maximizing productivity.

- Customized Gear Solutions: We collaborate closely with manufacturers to provide precision gears that align perfectly with their machines’ specifications, enhancing performance and extending equipment lifespan.

Contact us today