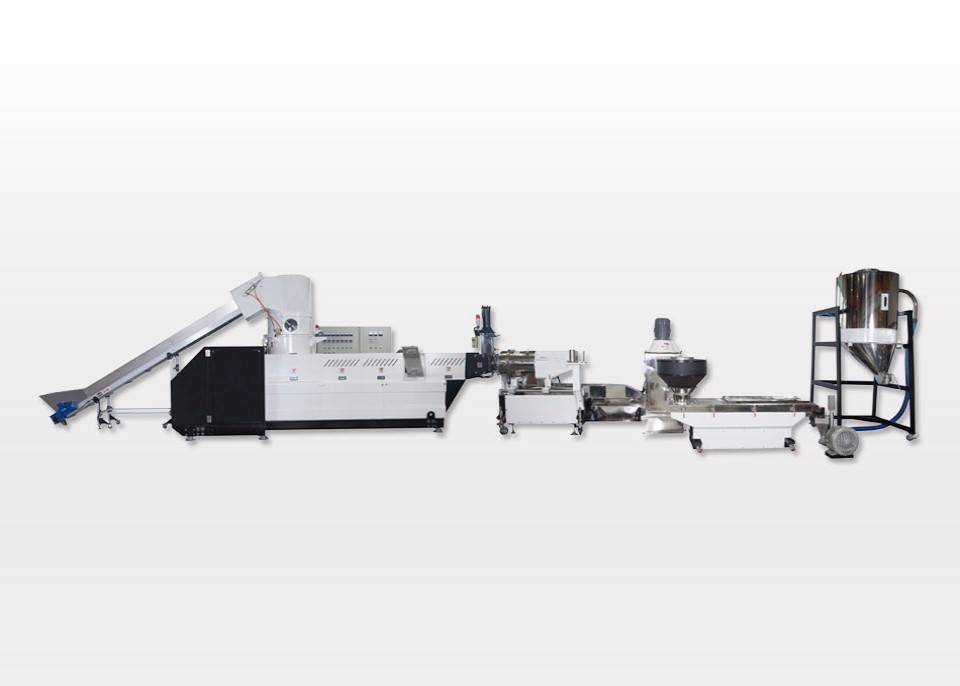

Recycling & Pelletizing Machinery

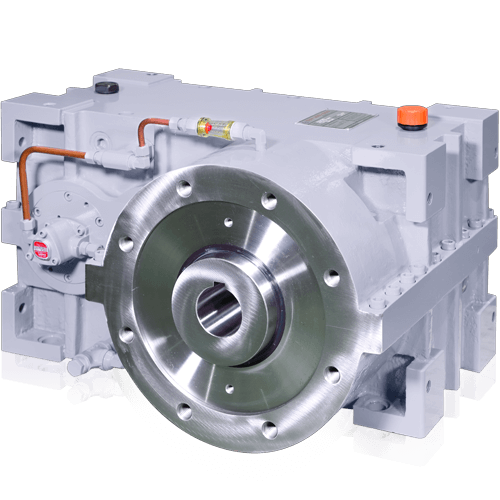

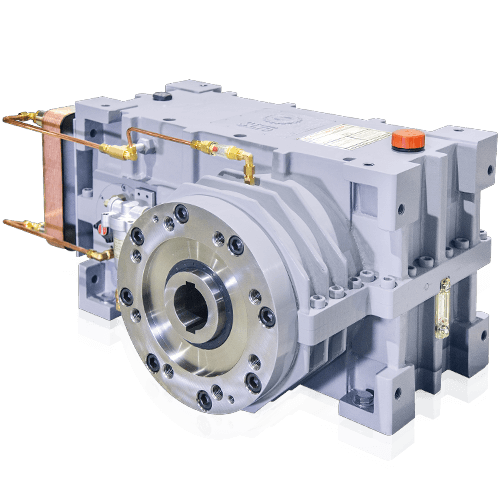

SUN LUNG Gearboxes Ensure Stable and Efficient Operation for Recycling and Pelletizing Machinery

In the recycling industry, reducing raw material costs while maintaining product quality is a top priority. Many manufacturers mix recycled materials with virgin plastics to create their final products. The purity and quality of the recycled granules are crucial to ensuring the end product meets industry standards. SUN LUNG provides reliable and stable gearboxes specifically designed for recycling and pelletizing machinery, ensuring consistent performance and uniform granule production.

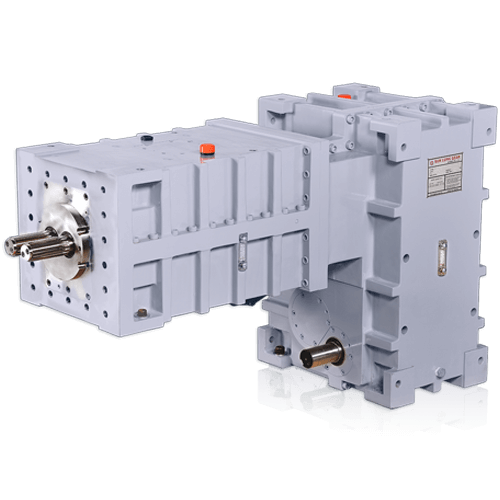

To cater to the diverse needs of the recycling market, SUN LUNG offers a wide range of gearbox solutions, from SL-50 to SLF-400. These gearboxes are tailored based on motor specifications and output capacity, delivering efficient and durable performance for various recycling applications.

Why Choose SUN LUNG Gearboxes for Recycling & Pelletizing Machinery?

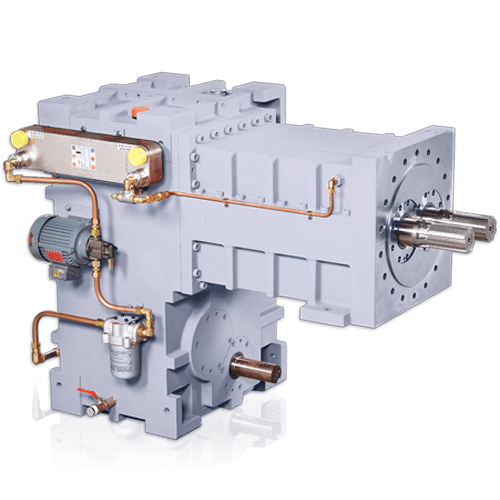

- Expertise as a Leading Gearbox Manufacturer – SUN LUNG is recognized as a trusted gearbox manufacturer, offering innovative and high-quality solutions for the recycling industry. Our gearboxes are built to handle the rigorous demands of recycling processes, ensuring long-term reliability.

- Top-Tier Gearbox Brands for Recycling Applications – As one of the leading gearbox brands, SUN LUNG delivers products designed with precision engineering and superior materials, guaranteeing stable working conditions and consistent output quality.

- Custom Gearbox Solutions for Specific Needs – SUN LUNG specializes in creating custom gearbox designs that are tailored to meet the unique requirements of recycling and pelletizing machinery. Whether you need specific motor compatibility or customized output capacities, our gearboxes provide the perfect solution.

SUN LUNG gearboxes help manufacturers reduce material costs while maintaining high-quality recycled production.

Contact us today