Single Screw Extruders

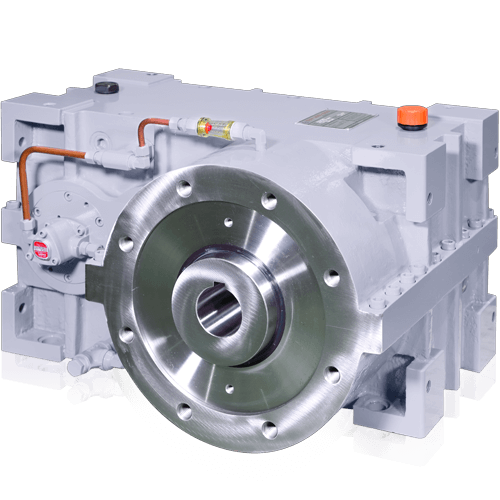

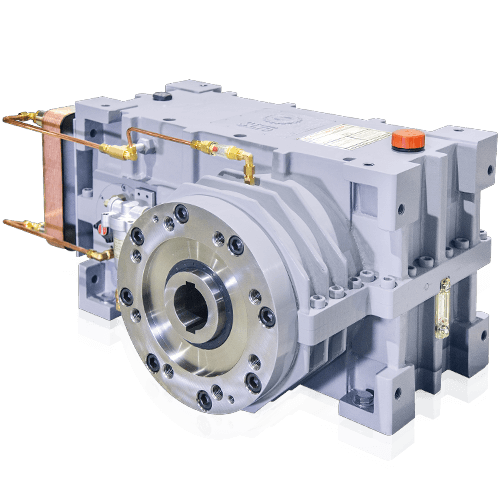

Single Screw Extruder Gearboxes by SUN LUNG—Designed for Precision and Durability

To satisfy the diverse demands of single screw extruders—including blow film, blow molding, recycling pelletizing machinery, and plastic pipe, sheet, and profile extrusion lines—SUN LUNG developed a unique extruder gearbox design tailored to customer requirements. We apply the highest precision gears and shafts to ensure maximum operational efficiency with minimal power consumption. Our gearboxes are equipped with SKF bearings and NOK oil seals for extended service life, and integrated with advanced cooling and lubrication systems to enhance reliability and overall gearbox performance.

Single Screw Extruders: Versatile Solutions for Plastic Manufacturing

Single screw extruders are widely adopted in the plastic processing industry for their versatility, efficiency, and cost-effectiveness. These machines support a broad range of applications including blown film extrusion, pipe and profile production, sheet extrusion, blow molding, and recycling pelletizing. SUN LUNG’s rear extraction-type extruder gearboxes are engineered for precision and performance, helping manufacturers achieve better consistency and output in these demanding environments.

Applications of Single Screw Extruder Gearboxes

- Blown Film Extrusion: Single screw extruders are essential for producing plastic films used in packaging, agriculture, and industrial applications. SUN LUNG’s gearbox design ensures precise torque transmission, maintaining consistent film thickness and exceptional product quality.

- Pipe and Profile Extrusion: In pipe and profile production, our gearboxes for single screw extruders deliver stable performance with reduced energy consumption—ideal for infrastructure, plumbing, and construction applications.

- Sheet Extrusion: For continuous operations in thermoforming and packaging sheet production, our gearboxes maintain high operational stability and deliver precise dimensional accuracy and surface finish.

- Recycling and Pelletizing: In harsh, contaminated environments, our durable gearboxes help transform post-consumer or industrial waste into uniform pellets. Their robust construction ensures consistent performance and long-term reliability for single screw extruder applications.

- Blow Molding: From bottles to containers, blow molding processes demand high torque and pressure. SUN LUNG gearboxes are designed to handle these challenges, supporting smooth operation and longer equipment life.

Why Choose SUN LUNG Gearboxes for Single Screw Extruders?

- Tailored Solutions: Every extruder gearbox is designed to match the exact needs of your application, ensuring maximum compatibility and performance for single screw extruders.

- Precision Engineering: With high-precision gears and shafts, our gearboxes minimize power loss and deliver stable torque output for consistent quality.

- Long-Term Reliability: Featuring SKF bearings, NOK oil seals, and advanced cooling and lubrication systems, SUN LUNG gearboxes offer durability you can trust.

- Energy Efficiency: Our efficient designs help reduce power consumption, offering an eco-friendly and cost-effective gearbox solution for single screw extruder operations.

Get consistent performance and longer service life for your single screw extruders with our precision-engineered gearboxes.

Contact us today