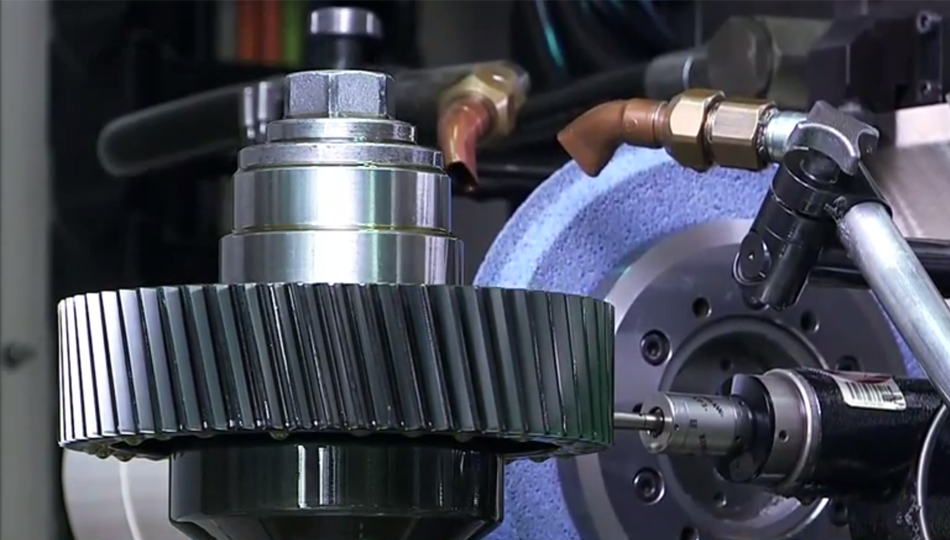

Precision Gears

To adapt to the higher demand of precision gears, Sun Lung had worked hard to put out the highest grade quality products for customers. The advanced equipment not only enable us to have the superior precision gear machining capability, but also have the special processing technique for complex diversified gear variation and gear profile modification. The machining modulus is from 3.5~50; the precision can be reached to highest DIN1 grade. Besides, Sun Lung had long been devoted to metal material, heat treatment and other related processing technique development. With 50 years practical experience and strict quality management, the Sun Lung precision gears product are your best choice.

FEATURE

- Applying the world's latest CNC hobbing & gear grinding instrument

- Conical Bevel Gear Precision Hobbing & Grinding Core Technology

- Diversified precision gear profile modification technology ensures the best gear precision

- The precision of gear can be reached to the highest DIN1~3 grade

- Coordinated with 11-axis CNC driving mode enables super speedy precision gear machining capability

- The MAX gear Grinding diameter of precision gears can be up to 2,000mm

- Customized design for requested material & heat treatment